As the VFD manufacturer in china, V&T has rich experience in electric drive fields. V&T V6-H series is a high performance vector control and torque control inverter.The product adopts close-loop vector control technology and torque control technology which are synchronized with the current international advanced technology, and it has the same excellent control performance with the international high-end frequency drive.

Sample provide:

YESSample freight payer:

BuyerTerm of payment:

T/T, L/C, D/PCustomized:

YESWarranty:

18 MonthsDelivery Time:

5-7 working days for standard series; 7-14 working days for customized AC drivesTransportation:

Express · Sea freight · Land freight · Air freightPackage:

Standard Export Package Carton/WoodAvailability:

OEM/ODM, Minmum Order RequestPlace of Origin:

ChinaShipping Port:

ShenzhenCertification:

CE, EAC, ISO9001, OHSAS18001, TS16949, SGS

Product Overview

Item

Description

Product Name

Frequency Inverter/ AC Drive

Model Number

V6-H-4TxxG/xxL

Power Range

0.75kW-500kW

Rated Input Voltage

3 phase 380V/480V

Rated Output Voltage

3 phase 0 to rated input voltage

Input Frequency

50Hz/60Hz

Applicable Motor

Asynchronous Motor

Control Mode

V/F Control, Vector Control, Sensor-less Vector Control, Sensor Vector Control, Vector Torque Control

Communication

Modbus 485 RTU

IP Class

Standard IP20

Overload Capacity

150% 1 minute, 180% 10 seconds, 200% 0.5 second, interval: 10 minutes (inverse time lag feature)

Feature

■ Vfd Motor Controller Open - loop vector, Closed - loop vector, Open - loop torque, Closed - loop torque control.

■ Inverter operates stably without tripping under any acceleration and deceleration time and any impact load.

■ Real torque control is realized through the independent current loop control, and online switching between torque control and speed control is supported.

■ Independent input and output port of high speed pulse, which can realize high speed pulse cascade function.

■ Accurate speed identification and rotor flux orientation, the torque can also respond quickly and operate stably when a load of 0.25hz breaks.

■ High-precision current detection and protection, high-precision hall to detect output current, realization of fast real-time control and protection of software and hardware, and assurance of performance and reliability of the whole machine.

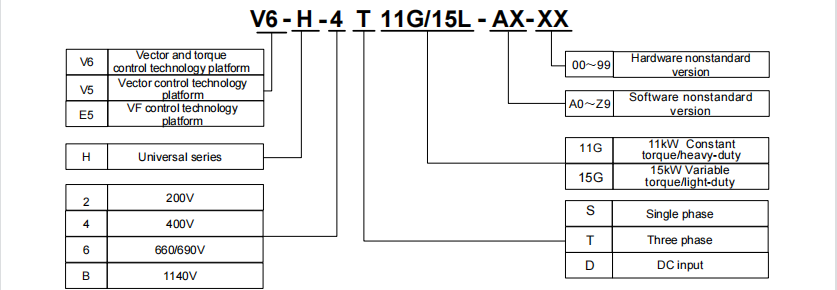

Model Explanation

Product Catalogue

V6−H−4T□□□G ;Three−phase 400V Constant torque/heavy−duty application

Power (kW)

0.75

1.5

2.2

3.7

5.5

7.5

11

15

18.5

22

30

37

45

55

75

Motor power (kW)

0.75

1.5

2.2

3.7

5.5

7.5

11

15

18.5

22

30

37

45

55

75

Output

Voltage (V)

Three-phase 0 to rated input voltage

Rated current (A)

2.5

3.8

5.5

9

13

17

24

30

39

45

60

75

91

112

150

Overload capacity

150% 1 minute, 180% 10 seconds, 200% 0.5 second, interval: 10 minutes (inverse time lag ;feature)

Input

Rated voltage/frequency

Three-phase 380V/480V; 50Hz/60Hz

Allowable voltage range

323V ~ 528V; Voltage imbalance ;≤3%; allowable frequency fluctuation: ±5%

Rated current (A)

2.8

4.2

6.1

10

15

19

26

33

43

50

66

83

100

123

165

Braking unit

Built-in as standard

Built-in as optional

Protection class

IP20

Cooling mode

Natural−cooling

Forced air cooling

Power (kW)

90

110

132

160

185

200

220

250

280

315

355

400

450

500

Motor power (kW)

90

110

132

160

185

200

220

250

280

315

355

400

450

500

Output

Voltage (V)

Three-phase 0 to rated input voltage

Rated current (A)

176

210

253

304

350

380

426

470

520

600

650

690

775

860

Overload capacity

150% 1 minute, 180% 10 seconds, 200% 0.5 second, interval: 10 minutes (inverse time lag ;feature)

Input

Rated voltage/frequency

Three-phase 380V/480V; 50Hz/60Hz

Allowable voltage range

323V ~ 528V; Voltage imbalance ;≤3%; allowable frequency fluctuation: ±5%

Rated current (A)

160*

196*

232*

282*

326*

352*

385*

437*

491*

580*

624*

670*

755*

840*

Braking unit

External braking unit needed

Protection class

IP20

Cooling mode

Forced air cooling

V6−H−4T□□□L Three−phase 400V Variable torque/light−duty application

| Power (kW) | 1.5 | 2.2 | 3.7 | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 | 55 | 75 | 90 | |

| Motor power (kW) | 1.5 | 2.2 | 3.7 | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 | 55 | 75 | 90 | |

| Output | Voltage (V) | Three-phase 0 to rated input voltage | ||||||||||||||

| Rated current (A) | 3.3 | 5 | 7.5 | 11 | 17 | 22 | 30 | 37 | 44 | 56 | 72 | 91 | 110 | 142 | 176 | |

| Overload capacity | 115% 1 minute, 160% 0.5 second, interval: 10 minutes (inverse time lag feature) | |||||||||||||||

| Input | Rated voltage/frequency | Three-phase 380V/480V; 50Hz/60Hz | ||||||||||||||

| Allowable voltage fluctuation range | 323V ~ 528V; Voltage imbalance: ≤3%; allowable frequency fluctuation: ±5% | |||||||||||||||

| Rated current (A) | 3.6 | 5.5 | 8.3 | 12 | 19 | 25 | 33 | 40 | 50 | 62 | 80 | 100 | 121 | 156 | 194 | |

| Braking unit | Built-in as standard | Built-in is optional | ||||||||||||||

| Protection class | IP20 | |||||||||||||||

| Cooling mode | Natural cooling | Forced air cooling | ||||||||||||||

| Power (kW) | 110 | 132 | 160 | 185 | 200 | 220 | 250 | 280 | 315 | 355 | 400 | 450 | 500 | 560 | ||

| Motor power (kW) | 110 | 132 | 160 | 185 | 200 | 220 | 250 | 280 | 315 | 355 | 400 | 450 | 500 | 560 | ||

| Output | Voltage (V) | Three-phase 0 to rated input voltage | ||||||||||||||

| Rated current (A) | 210 | 253 | 304 | 350 | 380 | 426 | 470 | 520 | 600 | 650 | 690 | 775 | 860 | 950 | ||

| Overload capacity | 115% 1 minute, 160% 0.5 second, interval: 10 minutes (inverse time lag feature) | |||||||||||||||

| Input | Rated voltage/frequency | Three-phase 380V/480V; 50Hz/60Hz | ||||||||||||||

| Allowable voltage range | 323V ~ 528V; Voltage imbalance ;≤3%; allowable frequency fluctuation: ±5% | |||||||||||||||

| Rated current (A) | 196* | 232* | 282* | 326* | 352* | 385* | 437* | 491* | 580* | 624* | 670* | 755* | 840* | 920* | ||

| Braking unit | External braking unit needed | |||||||||||||||

| Protection class | IP20 | |||||||||||||||

| Cooling mode | Forced air convection cooling | |||||||||||||||

*V6−H−4T110L and higher power products are equipped with external DC reactor as standard.

V6−H−2T□□□G Three−phase 200V Constant torque/heavy−duty application

|

Power (kW) |

0.4 |

0.75 |

1.5 |

2.2 |

||

|

Motor power (kW) |

0.4 |

0.75 |

1.5 |

2.2 |

||

|

Output |

Voltage (V) |

Three−phase 0 to rated input voltage |

||||

|

Rated current (A) |

3 |

5 |

7.5 |

10 |

||

|

Overload capacity |

150% 1 minute, 180% 10 seconds, 200% 0.5 second, interval: 10 minutes ;(inverse time lag feature) |

|||||

|

Input |

Rated voltage/frequency |

Three−phase or single−phase 200V~240V; 50Hz/60Hz |

||||

|

Allowable voltage range |

180V ~ 260V; Voltage imbalance≤3%; allowable frequency fluctuation: ±5% |

|||||

|

Rated current (A) |

3.8 |

5.5 |

8.3 |

12 |

||

|

Braking unit |

Built−in as standard |

|||||

|

Protection class |

IP20 |

|||||

|

Cooling mode |

Natural−cooling |

Forced air cooling |

||||

Technical Specification

|

Control characteristics |

Control mode

|

Vector control 1 |

Vector control 2 (Without encoder) |

Vector control 2 (With encoder ) |

|

Starting torque |

0.50Hz 180% |

0.25Hz 180% |

0.00Hz 180% |

|

|

Range of speed regulation |

1:100 |

1:200 |

1:1000 |

|

|

Precision of steady speed |

± 0.5% |

± 0.2% |

± 0.02% |

|

|

Torque control |

N |

Y |

Y |

|

|

Precision of torque control |

− |

±5% |

±5% |

|

|

Torque response time |

− |

<20ms |

<10ms |

|

|

Product functions |

Key functions |

Under-voltage regulation, switchover of run command source(operation panel, terminal and communication), speed tracing function, torque limit, multi− step frequency reference(up to 23 step frequency), motor data identification, S curve acceleration and deceleration, slip compensation, PID regulation, droop control, current limit, switch-over between torque control and speed control, manual torque boost and auto torque boost, programmable digital inputs and programmable digital outputs |

||

|

Frequency reference mode |

Parameter setting, operation panel UP/DN, terminal, terminal UP/DN, communication, analog ( AI1/AI2/AI3), pulse DI , etc. |

|||

|

Frequency range |

0.00 ~ 300.00Hz Note: In the control mode of vector control 1, frequency range from 0.0Hz to 3000.0Hz can be customized according to the customer demand |

|||

|

Start frequency |

0.00 ~ 60.00Hz |

|||

|

Acceleration time and deceleration time |

0.1 ~ 36000s |

|||

|

Dynamic braking |

Braking unit action voltage: 650 ~ 750V; operating time: 100.0s The braking unit can be built-in for V6−H−4T75G and below equipment |

|||

|

DC braking |

DC braking start frequency: 0.00 ~ 300.00Hz DC braking current: constant torque: 0.0 ~ 120.0%, variable torque: 0.0 ~ 90.0% DC braking time: 0.0 ~ 30.0s; DC braking function does not required waiting time to start to realize quick braking |

|||

|

Magnetic flux braking |

Enabled or disabled during deceleration are optional, the default setting is enabled |

|||

|

Unique functions |

Multi-function M key |

The unique multi-function key can be set to frequently used operations: such as JOG, emergency stop, switchover of run command source, switchover of parameters display mode, etc. |

||

|

Multiple parameters display modes |

Basic parameters display mode, fast parameters display mode, non−factory setting parameters display mode, last changed 10 parameters display mode |

|||

|

Parameters copy |

The standard operation panel can realize the parameters upload, download and display the copy progress. Users can set to forbid overwriting the uploaded parameters |

|||

|

Displayed and hidden parameters group |

The customer can select to display or hide the parameters group by themselves |

|||

|

Dual 485 communication ports |

Dual 485 communication ports support Modbus protocol (RTU). The maximum distance is 500 meters |

|||

Motor Wiring

It is forbidden to short circuit the 3 phase vfd output terminals or short circuit to ground, otherwise the internal components of the variable frequency inverter will be damaged.

Do not short circuit the output cable to the Electrical Motor Drive enclosure, otherwise electric shock may happen.

It is forbidden to connect the output terminal of the inverter to the capacitor or LC/RC noise filter with phase lead, otherwise, the internal components of the inverter may be damaged.

When contactor is installed between the inverter and motor, it is forbidden to switch on/off the contactor when the V&T Vfd Drive is running; otherwise, large current will flow into the industrial inverter, triggering the inverter protection action.

Length of cable between the AC drive converter and motor. If the cable between the frequency inverter and the motor is too long, the high−order harmonic leakage current of the output end will cause adverse impact on the AC inverter and the peripheral devices. Output AC reactor should be installed if the motor cable is longer than 100m, Refer to the following table for the switching frequency setting.

Installation dimension

|

|

V6−H−2T0.4G~V6−H−2T2.2G、V6−H−4T7.5G/11L And below power class

|

|

V6−H−4T11G/15L And above power class

Product appearance, installation dimensions, approximate weight

|

Voltage |

Model |

Appearance, installation dimension(mm) |

weight(kg) |

|||||||

|

W |

H |

D |

W1 |

H1 |

D1 |

T1 |

Hole ;d |

|||

|

200V |

V6−H−2T0.4G |

118 |

190 |

155 |

105 |

173 |

40.8 |

3 |

5.5 |

1.5 |

|

V6−H−2T0.75G |

175 |

60.5 |

4 |

2.2 |

||||||

|

V6−H−2T1.5G |

155 |

40.8 |

3 |

1.5 |

||||||

|

V6−H−2T2.2G |

175 |

60.5 |

4 |

2.2 |

||||||

|

400V |

V6−H−4T0.75G/1.5L |

118 |

190 |

155 |

105 |

173 |

40.8 |

3 |

5.5 |

1.5 |

|

V6−H−4T1.5G/2.2L |

118 |

190 |

175 |

105 |

173 |

60.5 |

4 |

5.5 |

2.6 |

|

|

V6−H−4T2.2G/3.7L |

||||||||||

|

V6−H−4T3.7G/5.5L |

||||||||||

|

V6−H−4T5.5G/7.5L |

155 |

249 |

185 |

136 |

232 |

69 |

8 |

5.5 |

4.5 |

|

|

V6−H−4T7.5G/11L |

||||||||||

|

V6−H−4T11G/15L |

210 |

337 |

200 |

150 |

324 |

88 |

2 |

7 |

8.5 |

|

|

V6−H−4T15G/18.5L |

||||||||||

|

V6−H−4T18.5G/22L |

289 |

440 |

215 |

200 |

425 |

88 |

2.5 |

7 |

17 |

|

|

V6−H−4T22G/30L |

||||||||||

|

V6−H−4T30G/37L |

||||||||||

|

V6−H−4T37G/45L |

319 |

575 |

212 |

220 |

553 |

90.5 |

2.5 |

10 |

25 |

|

|

V6−H−4T45G/55L |

||||||||||

|

V6−H−4T55G/75L |

404 |

615 |

255 |

270 |

590 |

86.5 |

3.0 |

10 |

35 |

|

|

V6−H−4T75G/90L |

||||||||||

|

V6−H−4T90G V6−H−4T110L |

465 |

745 |

325 |

343 |

715 |

151.5 |

3.0 |

12 |

55 |

|

|

V6−H−4T110G V6−H−4T132L |

||||||||||

|

V6−H−4T132G V6−H−4T160L |

540 |

890 |

385 |

370 |

855 |

205.5 |

4.0 |

14 |

85 |

|

|

V6−H−4T160G V6−H−4T185L |

||||||||||

|

V6−H−4T185G V6−H−4T200L |

||||||||||

|

V6−H−4T200G V6−H−4T220L |

||||||||||

|

V6−H−4T220G V6−H−4T250L |

700 |

1010 |

385 |

520 |

977 |

210 |

4.0 |

14 |

125 |

|

|

V6−H−4T250G V6−H−4T280L |

||||||||||

|

V6−H−4T280G V6−H−4T315L |

||||||||||

|

V6−H−4T315G V6−H−4T355L |

810 |

1358 |

425 |

520 |

1300 |

210 |

4.0 |

14 |

215 |

|

|

V6−H−4T355G V6−H−4T400L |

||||||||||

|

400V |

V6−H−4T400G V6−H−4T450L |

810 |

1358 |

425 |

520 |

1300 |

210 |

4.0 |

14 |

215 |

|

V6−H−4T450G V6−H−4T500L |

||||||||||

|

V6−H−4T500G V6−H−4T560L |

||||||||||

Applications

|

|

|

|

|

|

|

|

|

The use of variable frequency drive (VFD): a VFD is used to regulate the speed and torque of the Motor according to the variation of the load in order to improve the Motor energy efficiency. The High Performance Universal Inverter of Shenzhen V&T Technologies Co.,Ltd. is suitable for Printing Packing Machine VFD, Petrochemical, Textile, Cable Machinery Inverter, Food ,Packaging, Electric Vehicles, Plastic Machinery, Metal Products Equipment, Centrifuges and High-end applications requiring closed-loop vector or torque control.

Previous:

3.7kW-15kW V6 Series High Performance Universal InverterNext:

75kW-220kW V6 Series High Performance Universal InverterIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

Categories